EVSE ODM Customization

13 Years Electric Vehicle Supply Equipment Manufacturer

You need more than just a single EVSE ( Electric Vehicle Supply Equipment ) product, you need a veteran EVSE supplier who has been in the field for many years to build your brand and grow your profits. Let evseODM help you customize EVSE and achieve business success.

12

YEARS EXPERIENCE

27

ODM PROJECTS

78

OEM PROJECTS

42

EXPORTING COUNTRIES

EV Charger For HOME USE

They are usually installed in garages. The design of household charger should be easy to install and operate.

EV Charger For COMMERCIAL USE

They are usually installed in public places, like hotels and parking lots. The design is completely different from the one for home.

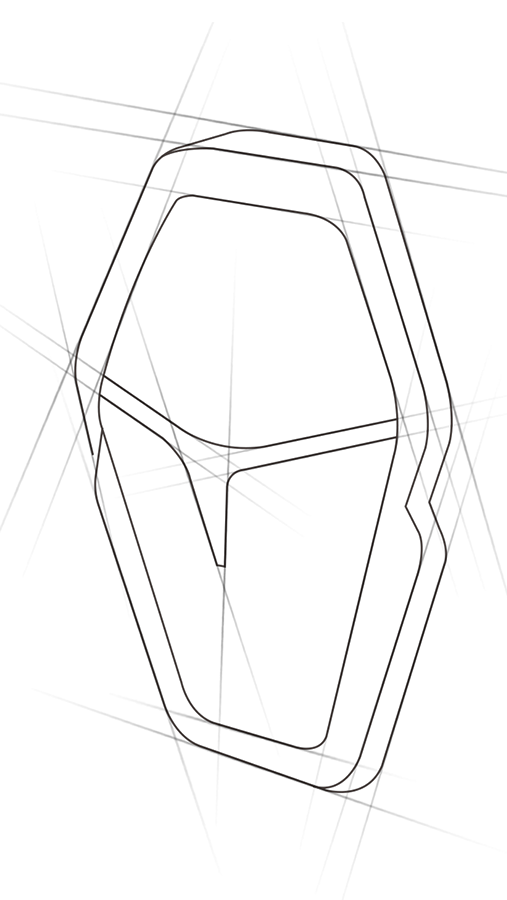

Want To ODM Customized EV Chargers?

With over 12 years of experience, evseODM is your one-stop shop when it comes to EV charging solutions. We can provide

- More perfect design scheme of EVSE

- Faster customization cycle of EVSE

- More appropriate customization cost of EVSE

- More stable performance of EVSE

evseODM Can Meet All Your Requirements For Customization

We know what kind of EV Chargers customers need. After full communication, we can always provide customers with faster and better customization services, and we know what details need special attention in the design of EV chargers, and how to adjust the charging procedures for different regions, so that customers can get their expected EV Chargers on time and accurately, or even better.

Austria, 2020

In this project, the customer's demand for Electric Vehicle Supply Equipment was to reach IP67 waterproof level. All EV charging information needed to be fully displayed on the LCD screen, and the temperature of the EV charging plug could be monitored in real-time. In the pro version, the portable EV charger's control box automatically could recognize different adapters to limit the maximum charging current.

Germany, 2020

This was an EV charging station project in public places, which was mainly applicable to hotels, supermarkets, companies and other public places. We should not only consider the stability of EV charging stations under high-frequency use, but also consider restricting users' permissions and realizing the function of how to charge(collect fees).

Norway, 2019

The climate in Norway was extremely cold. In some areas, it could be as low at -40 °C outside at night which had high requirements for the material and structural design of EV Charger especially when considering EV charging cables that needed to remain soft yet durable under these conditions so they didn’t snap or break due to extreme temperature changes over time.

Italy, 2021

This was an EV charging station designed for an Italian airport. The EV charger was equipped with a special RFID card writer, which could be used freely by all staff with RFID cards and could save relevant usage records. In addition, the customer required that the EV charger screen could display the customized information.

France, 2021

The customer requested to customize a high-end spring EV charging cable with good flexibility. Its wire needed to be perfectly winded and the diameter had to be as small as possible. Besides, the customer had strict requirements for EV Charger's overall appearance. The EV charging cable sheath material had to be difficult to deform, wear-resistant and anti-aging with a high degree of recognition. In the end, the customer was very satisfied after receiving the product.

Germany, 2021

The customer required that the portable EV Charger's control box could set delayed EV charging and charging duration, and in particular, support switching multiple currents, which was convenient for car owners to choose by themselves. This project was less challenging since all functional modules were ready-made and could be matched and assembled according to customer's needs.

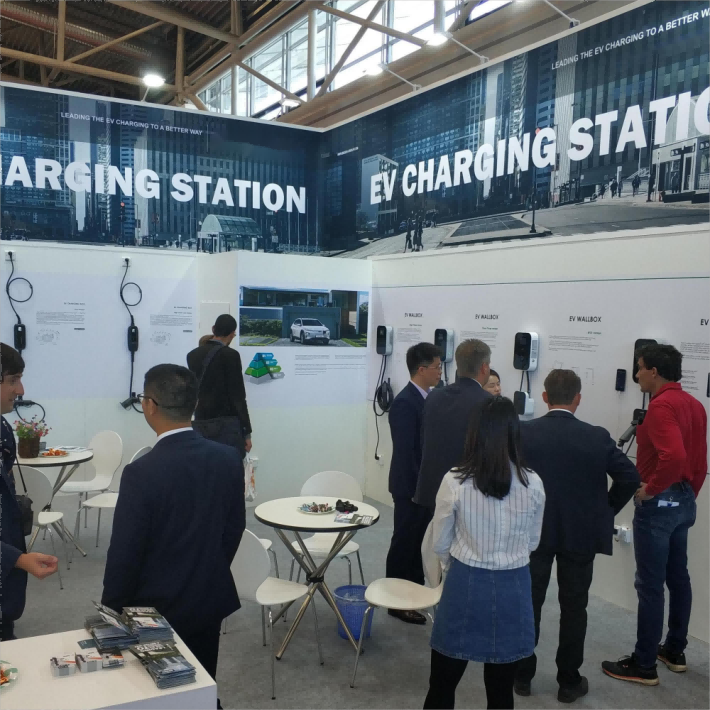

Who Is evseODM?

We are a professional manufacturer of customized electric vehicle supply equipment for global customers, focusing on providing complete electric vehicle charging product design solutions for product appearance, function, program, packaging, etc. Over the past 12 years, we have served customers in more than 42 countries and provided customers with 78 perfect EVSE ODM projects.

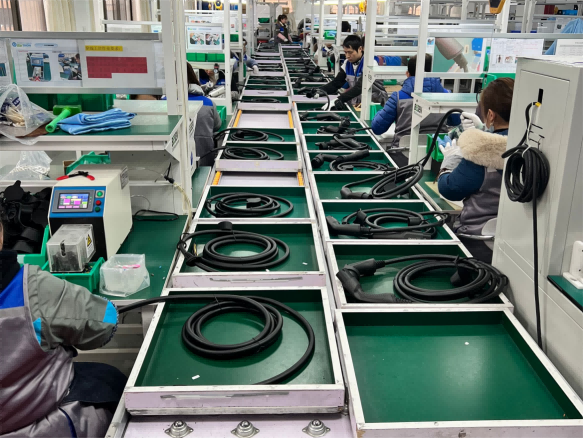

We have rich experience in EVSE ODM services from EV Chargers design and manufacturing and know how to provide customers with the best personalized EV Chargers. Our factory has a complete EVSE supply chain system and advanced management system to reduce costs for customers. And our company has a strong EVSE production capacity and can supply various electric vehicle supply equipment for customers in a timely and effective manner.

We are evseODM, a manufacturer committed to providing customers with more cost-effective evse customized services.

Why Choose evseODM?

We are a professional EVSE manufacturer, committed to providing customers with perfect EV supply equipment customization solutions. The EV Charger we design and produce operates stably in more than 42 countries and regions, so that our customers don’t have to worry about adaptability and can provide a better charging experience for end users.

12 Years’ Professional Experience

We have been focusing on EV charging for 12 years.

Personalized EVSE Customization Service

We provide you with professional EVSE ODM services to customize an EVSE of your own brand.

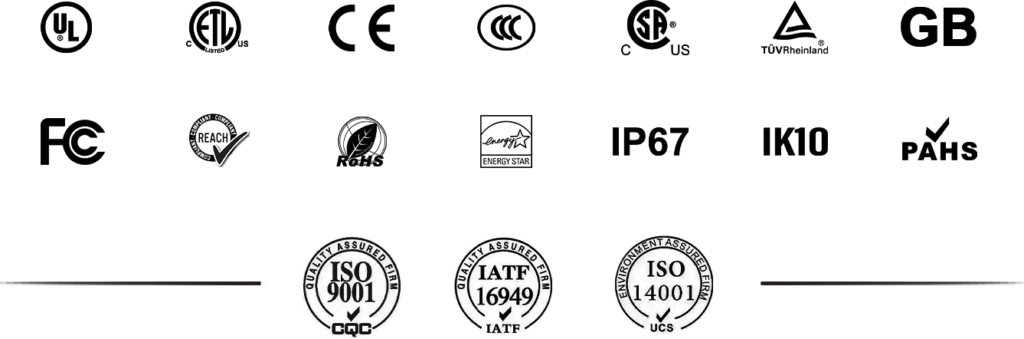

Strong EVSE R&D Capability

It has various patents and complete certifications.

Strong Adaptability

Complete Certifications

IP Rating

High Stability

Comprehensive Product Line

Perfect EV Charging Solutions

Professional Technical Team

Rich Project Experience

Complete Delivery Process

Professional Process Technology

Positive Reviews For evseODM From 40+ Countries

evseODM is a leading EVSE manufacturer and supplier, providing high quality EVSE products to customers worldwide. We are excited to offer our customers the EV charging equipment, which is a top-of-the-line product that offers superior performance and quality. We believe that it will provide our customers with the excellent performance and quality they expect from us. Thanks for choosing evseODM!

evseODM is a leading manufacturer of electric vehicle charging equipment. They offer a wide range of EVSE to suit any need. I had the opportunity to test out their latest EV Charger, and I was very impressed. I also appreciate the fact that evseODM offers a professional systematic EV charging solutions, so I can find the perfect evse for my needs. Overall, I’m very impressed with evseODM and would definitely recommend them to anyone looking for quality EV charging equipment.

Mike Sendler

As the electric vehicle market continues to grow, so does the need for evse manufacturers that can provide high-quality EV Charger at a competitive price. evseODM is one such manufacturer, their EV Chargers are designed for both home and commercial use, and they offer a variety of different pricing options to fit every budget. We believe that they are a great option for anyone in the market for an EVSE dealer.

Delmar Byers

evseODM offers a wide range of EVSE like EV adapters, EV cords, and EV wall chargers. Their EV products are backed by a one-year warranty, and their customer service team is available 24/7 to help EV customers with any questions or concerns. Overall, evseODM is a top-notch manufacturer of EV charging stations and accessories, and they should be your go-to choice when you’re ready to purchase an EV charger for your home or business.

Charmaine Tobey

FAQs About EVSE Customization&Wholesale From evseODM

evseODM has been wholesaling EVSE for 12 years and we have encountered all kinds of problems, here are the most important concerns of our customers before closing the deal.

What are the main advantages of finding a Chinese factory to customize EVSE?

China is the world's largest EV market, where the upstream and downstream industry chains are more mature and stable and the EVSE costs will be lower.

How long does the EVSE customization project (ODM) take?

This depends on the specific needs of the EVSE customization project and the current project schedule. Usually, it takes 6-8 weeks.

How much will an EVSE customization project cost?

This depends on the functions and parameters of the EVSE customization products. Generally, it costs 20,000 to 50,000 US dollars.

Which region has a better EV market?

It is generally believed that the European and North American markets are blooming and developing more rapidly while Southeast Asia, South America, and the Middle East markets have greater potential although they aren’t big right now.

Can I come to China to visit your factory?

Of course, you are welcomed. Many customers are amazed by our production capacity and management efficiency. But our factory takes appointments, so before arranging the itinerary, please confirm the visiting date with our sales personnel.

I already have the blueprint. Can you help me implement it?

Yes, and actually we prefer this kind of pattern since it allows us to focus on the feasibility analysis of the product and makes early communication more efficient.

Do you have a ready-made EV Charger for me to test the quality?

Yes, we have a lot of EV Chargers that are being sold stably. There are various types. You can choose the one that meets your needs and conduct preliminary testing.

I'm not familiar with the EVSE field, can I customize EVSE?

Don't worry, we have a lot of clients who are new to this field. We will communicate with our customers in detail and provide them with professional product suggestions.

EV charging station and portable EV charger, which one should I start with?

This should be decided according to your own market positioning and local demand environment. But if you are new to this field, we recommend starting with a portable EV charger, which is relatively simpler.

What if something goes wrong during the EVSE customization process?

We have customized various EVSE projects so far, and there have been no problems. And we have a complete contract of the customization project to strictly protect the rights and interests of every customer. For any loss due to our fault, we are fully responsible.

What is your most important advantage?

Our rich customization experience can ensure that our customers avoid all unnecessary losses in the process and complete their exclusively EVSE customized projects quickly and accurately.

Complete Certifications of evseODM

Now Contact Us

Start Customizing A Perfect EV Charging Equipment for you ! →

After confirming the requirements, we will provide you with professional product suggestions according to your actual situation, so that you can be more clear about your customization project

Usually, we will reply to your message within 6 working hours